|

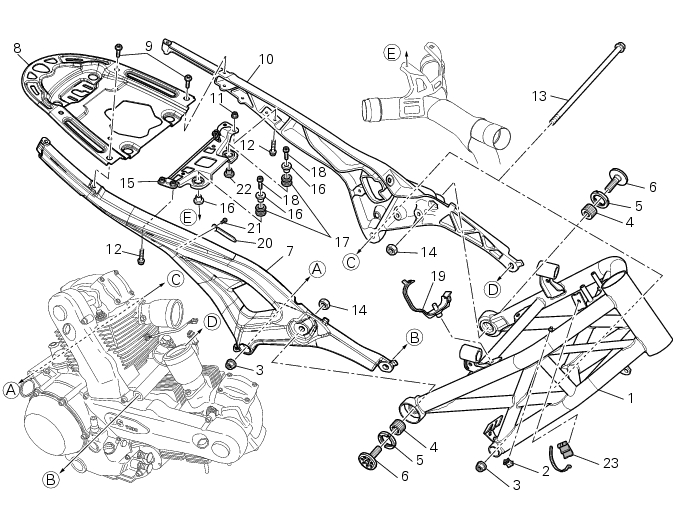

17 -

|

|

1

|

|

2

|

|

3

|

|

5

|

|

8

|

|

9

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

16

|

|

18

|

|

19

|

|

20

|

|

21

|

|

22

|

|

23

|