|

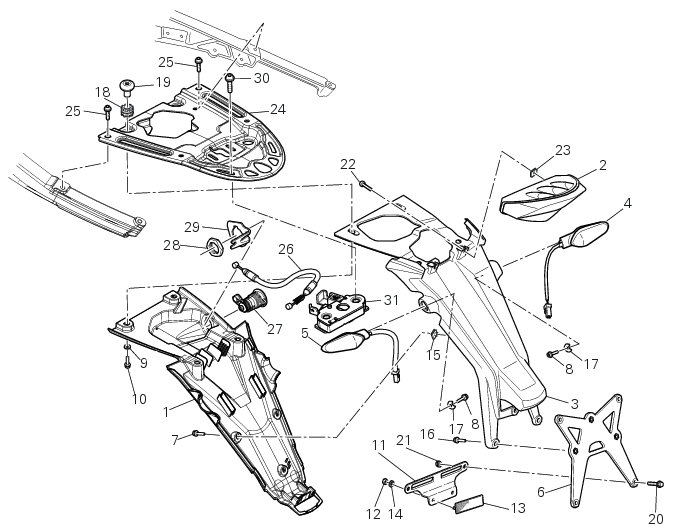

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

16

|

|

17

|

|

19

|

|

20

|

|

21

|

|

22

|

|

24

|

|

25

|

|

26

|

|

27

|

|

28

|

|

29

|

|

30

|

|

31

|