|

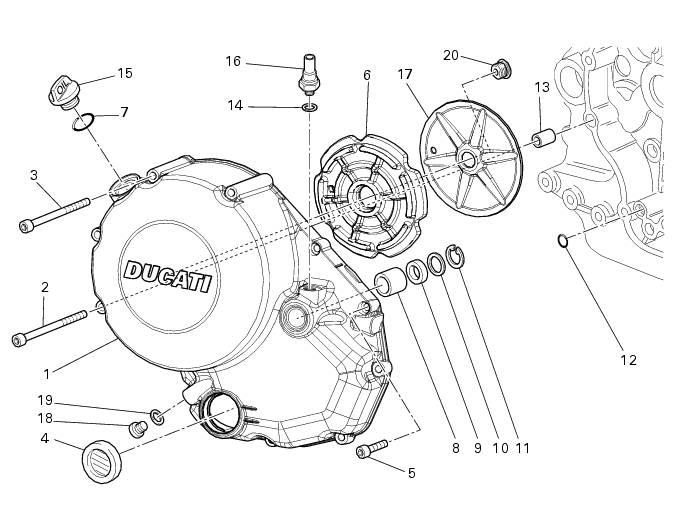

2

|

|

3

|

|

5

|

|

7

|

|

8

|

|

10

|

|

11

|

|

12

|

|

15

|

|

17

|

|

18

|

|

20

|

|

Disconnect the oil pressure sensor

|