|

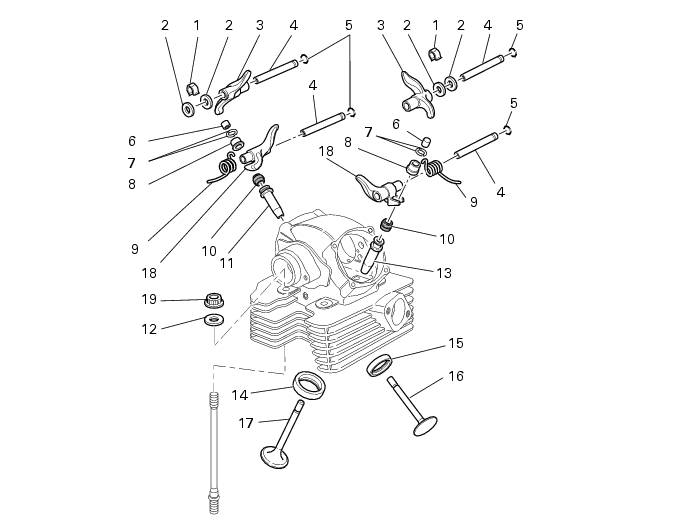

1

|

|

2

|

|

5

|

|

9

|

|

10

|

|

12

|

|

17

|

|

19

|

|

Remove the timing belts and the timing belt pulleys

|

|

-

|

Service limit: 0.03 mm.

|

|

-

|

|

-

|