|

2

|

|

8

|

|

9

|

|

11

|

|

12

|

|

13

|

|

18

|

|

19

|

|

20

|

|

23

|

|

24

|

|

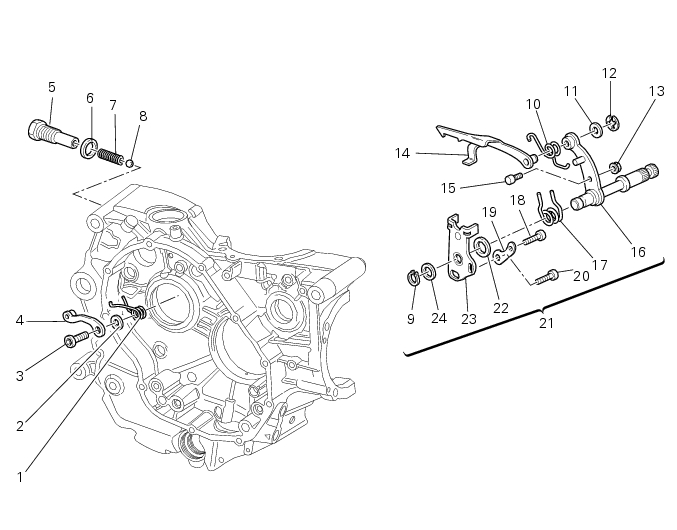

Remove the generator cover and flywheel-generator assembly

|

|

Refit the flywheel/generator assembly and generator cover

|

|