|

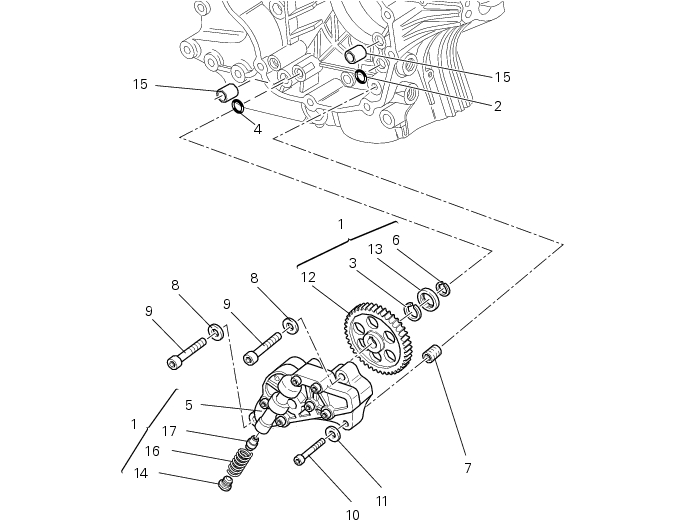

2

|

|

3

|

|

4

|

|

6

|

|

9

|

|

10

|

|

13

|

|

14

|