|

1

|

|

2

|

|

6

|

|

8

|

|

11

|

|

12

|

|

13

|

|

-

|

|

-

|

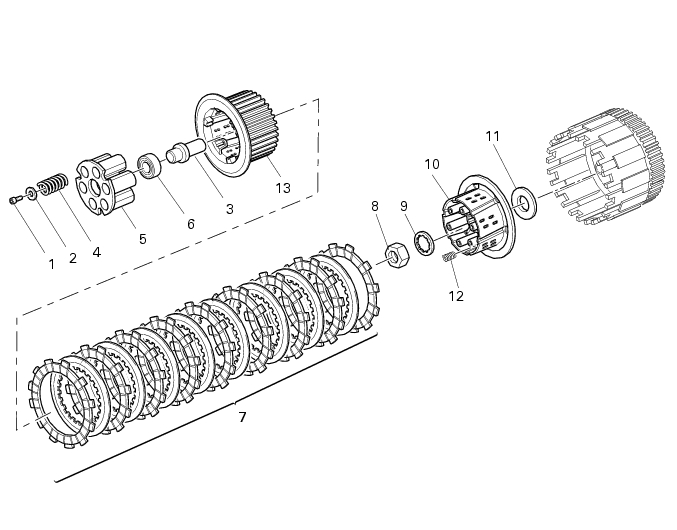

reduces the amount of driver effort required to disengage the clutch. The clutch lever effort is significantly reduced, without compromising the feel of the lever to the rider (servo-assisted).

|

|

-

|

Minimum length: 41 mm.

|