|

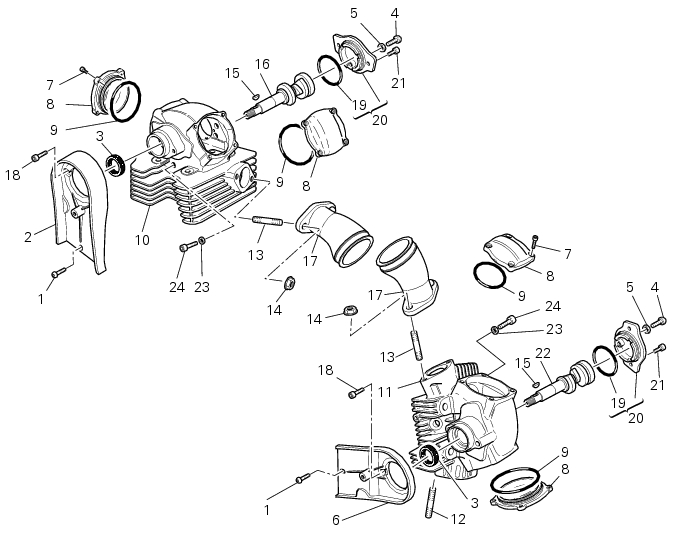

1

|

|

4

|

|

5

|

|

7

|

|

9

|

|

12

|

|

13

|

|

14

|

|

15

|

|

18

|

|

19

|

|

20

|

|

21

|

|

24

|

|

Disconnect ECU connector from main wiring harness

|

|

|

Remove the timing belts and camshaft timing belt pulleys on the heads

|

|

Remove the timing belts and camshaft timing belt pulleys on the heads

|

|

|

-

|

service limit: 0.1 mm.

|

|

Refit the timing belt pulleys on the heads and the timing belts

|

|

|

Refit the camshaft and the timing belt pulleys on the heads

|

|